StanSolv A-15

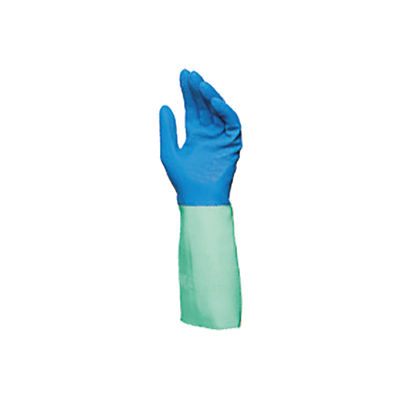

Excellent comfort and dexterity despite the high mechanical strength

-

CAT. 3

0334

0334

-

4101

4101

-

Specific advantages

Durability

Durability

Productivity

Productivity

- Chlorinated finish provides easy on/off.

Specific features

Unique Z-Pattern Grip channels liquids away from glove surface providing an enhanced grip in wet applications.

Applications

Automotive/mechanical industry

- Automotive assembly

- Handling oily mechanical parts

- Part degreasing

Mechanical industry

- Assembly of small oily parts

- Chemical treatment of metals

- Etching / degreasing

Food industry

- Food handling

- Food preparation

Chemical industry

- Handling and transporting chemicals (solvents)

Product detail

| Material | Nitrile |

|---|---|

| Colour | green |

| Interior finish | Chlorinated |

| Exterior finish | Non-slip grip |

| Length (inches) | 13.0” |

| Thickness (inches) | 0.015” (15 mil) |

| Size | 6 7 8 9 10 11 |

| Packaging | 12 pairs/bag 72 pairs/carton |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| 1,1,1-Trichloroethane 99% | 71-55-6 | 75 | 3 | ASTM F739 | 1 |

|

| 2-Butoxyethanol (Butyl Cellusolve) 99% | 111-76-2 | >480 | 6 | ASTM F739 | 4 |

|

| 2-Ethoxyethanol (Cellosolve) 99% | 110-80-5 | 224 | 4 | ASTM F739 | NT |

|

| 2-Ethoxyethyl acetate (Cellosolve Acetate) 99% | 111-15-9 | 138 | 4 | ASTM F739 | NT |

|

| 2-Propanol (Isopropanol) 99% | 67-63-0 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Acetic acid 10% | 64-19-7 | >480 | 6 | ASTM F739 | 4 |

|

| Acetic acid 50% | 64-19-7 | >480 | 6 | ASTM F739 | 4 |

|

| Acetic acid 99% | 64-19-7 | 93 | 3 | ASTM F739 | NT |

|

| Butyl Acetate 99% | 123-86-4 | 55 | 2 | ASTM F739 | 4 |

|

| Cumene 98% | 98-82-8 | 191 | 4 | ASTM F739 | NT |

|

| Cyclohexane 99% | 110-82-7 | >480 | 6 | ASTM F739 | NT |

|

| Diethylamine 98% | 109-89-7 | 16 | 1 | ASTM F739 | 3 |

|

| Dimethylformamide 99% | 68-12-2 | <15 | 1 | ASTM F739 | 1 |

|

| Formaldehyde 37% | 50-00-0 | >480 | 6 | ASTM F739 | 4 |

|

| Isobutyl alcohol 99% | 78-83-1 | >480 | 6 | ASTM F739 | 4 |

|

| Isophorone diisocyanate 98% | 4098-71-9 | >480 | 6 | ASTM F739 | NT |

|

| Kerosene mixture | 8008-20-6 | >480 | 6 | ASTM F739 | 4 |

|

| m-Cresol 97% | 108-39-4 | 224 | 4 | ASTM F739 | NT |

|

| Methanol 99% | 67-56-1 | 50 | 2 | ASTM F739 | 4 |

|

| n-Heptane 99% | 142-82-5 | >480 | 6 | ASTM F739 | NT |

|

| N-methyl-2-Pyrrolidone 99% | 872-50-4 | 18 | 1 | EN 374-3:2003 | 1 |

|

| Naphtha mixture | 8030-30-6 | >480 | 6 | ASTM F739 | 4 |

|

| Naphtha VM&P mixture | 8032-32-4 | >480 | 6 | ASTM F739 | NT |

|

| Nitric acid 50% | 7697-37-2 | 277 | 5 | ASTM F739 | 3 |

|

| Phosphoric acid 75% | 7664-38-2 | >480 | 6 | ASTM F739 | NT |

|

| Phosphoric acid 85% | 7664-38-2 | >480 | 6 | ASTM F739 | NT |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Styrene 99% | 100-42-5 | 18 | 1 | EN 374-3:2003 | NT |

|

| Sulfuric acid 96% | 7664-93-9 | 34 | 2 | EN 374-3:2003 | NT |

|

| t-Butyl Methyl Ether 98% | 1634-04-4 | 238 | 4 | ASTM F739 | 4 |

|

| Tert. Amyl Methyl Ether 96% | 994-05-8 | >480 | 6 | ASTM F739 | 4 |

|

| Tetrachloroethylene (Perchloroethylene) 99% | 127-18-4 | 260 | 5 | ASTM F739 | 4 |

|

| Toluene 99% | 108-88-3 | 18 | 1 | ASTM F739 | 2 |

|

| Trichloroethylene 99% | 79-01-6 | 12 | 1 | ASTM F739 | NT |

|

| Triethanolamine 98% | 102-71-6 | >480 | 6 | ASTM F739 | 4 |

|

| Turpentine mixture | 8006-64-2 | >480 | 6 | ASTM F739 | 4 |

|

| Unleaded gasoline mixture | 8006-61-9 | >480 | 6 | ASTM F739 | 4 |

|

| Xylene 99% | 1330-20-7 | 32 | 2 | EN 374-3:2003 | 1 |

|

*not normalized result

More gloves

Pylox V-10

Hand-specific, curved-finger design for low hand fatigue, excellent fit.

Pylox V-20

Hand-specific, curved-finger design for low hand fatigue, excellent fit.

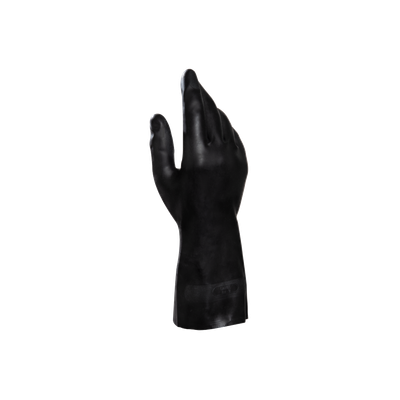

Trident 286

Excellent mechanical performance for long-lasting chemical protection

Jersette 301

Maximum comfort for long-term work in aggressive environments. Made from FSC® certified latex.

Jersette 315

Additional and comfortable protection for long-term work in agressive environments

Stansolv A10

The chemical protection of nitrile combined with excellent mechanical resistance

StanSolv A14

Unique Z-pattern grip provide secure handling of hard-to-grasp items

StanSolv A-15

Excellent comfort and dexterity despite the high mechanical strength

UltraNeo 450

Extremely supple with freedom of movement for standard chemical protection

UltraNeo 420

Extremely supple with freedom of movement for standard chemical protection

Pylox V-20

Hand-specific, curved-finger design for low hand fatigue, excellent fit.

Stansolv A10

The chemical protection of nitrile combined with excellent mechanical resistance

StanSolv A14

Unique Z-pattern grip provide secure handling of hard-to-grasp items

New

New

Ultranitril 358

Designed with an embedded optimal grip to safely handle tasks in dry & greasy environments

New

New

Ultranitril 410

Ideal glove for operations where cut and chemical protection are required, offering excellent durability and optimal grip.

Trident 286

Excellent mechanical performance for long-lasting chemical protection

To contact us

If you would like to ask us a commercial question about our products or if you would like to have more technical information about our gloves and their use, please fill out one of the forms proposed below.